|

| December 13, 2016 | Volume 12 Issue 46 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

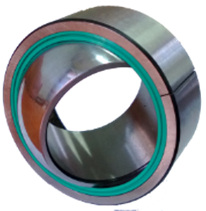

Big advance in spherical bearings for aircraft

DuPont and Fujian Longxi Bearing have teamed up to achieve a breakthrough in the use of self-lubricating spherical bearings in aircraft design. The aim is to improve performance and reduce costs for aerospace companies. The collaboration brings spherical bearing design and wear-resistant liner expertise together into a new, superior-performing bearing family.

In this case, DuPont and Fujian Longxi worked together to develop self-lubricating bearings for use in the actuation of airframe control systems. Fujian Longxi is the only Navair (AS81820 Type A, MS standards) certified company in China. These bearings will play a vital role in flight-critical tasks such as flight control systems, landing gear, and a wide range of other aircraft functions. The new development should also aid in satisfying demanding offset requirements, allowing for greater trade opportunities between countries.

The DuPont Vespel bearing liner has been successfully applied to the Fujian Longxi spherical bearing, allowing the bearings to meet the stringent new standards of SAE AS81820 type "A," and attaining maintenance-free certification for four times as long as the industry average. This means longer maintenance intervals, which in turn can lead to lower cost in operation, less maintenance time, and more time in the air.

While standard maintenance intervals are 25,000 cycles, the DuPont and Fujian Longxi solution allows for at least 100,000 cycles. During the testing phase, Fujian Longxi's bearings greatly exceeded the 100,000 cycles mark, with a large margin of safety and certifiable life still available. This is a critical breakthrough for aerospace companies that must meet stringent safety, environmental, and performance standards in a cost-efficient manner -- and who need to optimize life-cycle and maintenance of parts, particularly metal assemblies that cause wear and friction.

Meeting the AS81820 Type "A" standard was made possible through the global cooperation between these two industry technology leaders and was facilitated by the initiative and guidance of Allawos & Company, a global management consulting firm located in Glendora, CA.

Effectively applying liners to spherical bearings requires overcoming challenges such as low friction and wear resistance, damage to the contact surface, effective bonding of the liner to the spherical shape, and adapting to a broad range of sizes.

DuPont Vespel CP wearstrips meet these challenges through the product's high resistance to wear, low friction over a broad range of spherical bearing size, and design options. It reduces abrasion, corrosion, adhesion, fatigue, and wear problems, performing under conditions where most other composites solutions would fail.

While DuPont Vespel CP materials have long been used in aircraft engines. This is the first time they have been used in aircraft actuation systems. Overall, they should bring huge performance benefits and cost savings to customers in the aerospace sector.

As a backgrounder, you can view a video about the use of DuPont Vespel and Kalrez parts in aircraft engines here.

Source: DuPont Performance Materials

Published December 2016

Rate this article

View our terms of use and privacy policy